Numerical study of conduction heat transfer from toroidal shaped surfaces into an infinite domain

Abstract

The mathematical formulation for steady conduction heat transfer from a toroidal geometry into an infinite medium is presented. The torus is in thermal communication with the infinite medium through a heat transfer coefficient at the torus' external surface. The mathematical formulation is presented using the Toroidal coordinate system; a finite element grid is developed usign this coordinate system as the basis for development. Mesh refinement studies indicate convergence of the numerical solutions to a very high accuracy. Results are presented in tabular and graphic form for diameter ratios ranging from 1.1 to 10 and for the Biot modulus ranging from 0.01 through to 10 exp 20.

Heat Transfer 10thEdition by JP Holman.pdf. Mon Elvin B Jarabejo. Download Full PDF Package. A short summary of this paper. Heat conduction is one of the heat transfer mechanisms which smooth temperature or thermal gradient (QPedia, n.d, Spring, 2008). The material heat transfer coefficients are vital parameters as far as heat transfer through conduction is concerned, since the characteristically define the conduction properties of a given material. Figure 1.1: Conduction heat transfer The second heat transfer process is convection, or heat transfer due to a flowing fluid. The fluid can be a gas or a liquid; both have applications in aerospace technology. In convection heat transfer, the heat is moved through bulk transfer of a non-uniform temperature fluid.

- Schneider, P J., Conduction Heat Transfer, Addison. Conduction Heat Transfer, Prentice-Hall. 5.7 The heat transfer coefficient for air flowing.

- Conduction Heat Transfer by Schneider, P J and a great selection of related books, art and collectibles available now at AbeBooks.co.uk.

- Conductive Heat Transfer;

- Coordinates;

- Toroids;

- Computational Grids;

- Finite Element Method;

- Fluid Mechanics and Heat Transfer

- Open Access

- Total Downloads : 856

- Authors : B. K. Bharti, Dr. S. Singh, K. S. Deshwal

- Paper ID : IJERTV1IS8605

- Volume & Issue : Volume 01, Issue 08 (October 2012)

- Published (First Online): 29-10-2012

- ISSN (Online) : 2278-0181

- Publisher Name : IJERT

- License: This work is licensed under a Creative Commons Attribution 4.0 International License

Computational Study Of Steady State Conduction Heat Transfer With Different Cross-Section Using Altair® Hyperworks®

Computational Study Of Steady State Conduction Heat Transfer With Different Cross- Section Using

Altair® Hyperworks®

B. K. Bharti1 , Dr. S. Singp, K. S. Deshwal3

1M. Tech Scholar, 2Associate Professor, 3M. Tech Scholar

Department of Mechanical Engineering,

Bipin Tripathi Kumaon Institute of Technology, Dwarahat, Almora, Uttarakhand (India), 263653

In this study, the effect of temperature distribution with constant heat flux is considered. The study is considered on the Rectangular & Triangular profile block cross-section. This study is performed using Fourier Law of steady state heat conduction which depict the first law of thermodynamics. In the governing equation Fourier law is applied with the case of no internal heat generation to solve a one-dimensional heat conduction problem. The Problem is solved computationally using Altair Hyperworks Software. Analytical results were obtained for Rectangular & Triangular cross-section and these can be used to build up the Heat flow variation. The heat flux is maintained at constant value and temperature distribution within the section is obtained. Due to temperature difference heat will flow from higher temperature to lower temperature. The material of solid block cross-section provides conductive resistance. Hence, this is a conduction mode of heat transfer. The heat transfer takes place in one dimension only and properties are considered to be isotropic with two different Material Brass & Steel.

Keywords: Rectangular & Triangular Block cross-section temperature distribution.CAE

Software Altair Hyper work.

As we explore the propagation of energy, we must take into account the science of thermodynamics, which allows us to predict the trajectories of the processes, and the science of heat transfer for knowing the modes by which energy is

propagated from one system to other systems. We know that heat is not temperature because heat is energy in transit. Heat can exist in rotational, vibration and translational motions of the particles of a system, whereas temperature is the measurement of the average of the kinetic energy of the particles of a substance. The average of the molecular

kinetic energy depends on the translational motion of the particles of a system. The energy absorbed or stored by a substance causes an increase in the kinetic energy of the particles that form that substance. This kinetic energy or motion causes the particles to emit heat, which is transferred to other regions of that substance or towards other systems with a lower energy density.

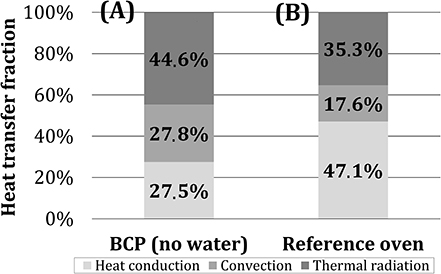

To understand heat transfer we have to keep in mind that heat is not a substance, but energy that flows from one system toward other systems with lower density of energy. Heat is temperature difference and the surroundings. In most of the processes heat is either given up or absorbed, so there is transfer of heat. There are three fundamental types of heat transfer: conduction, convection and radiation. All three types may occur at the same time, and it is advisable to consider the heat transfer by each type in any particular case

Heat transfer generally takes place by three modes such as conduction, convection and radiation. Heat transmission, in majority of real situations, occurs as a result of combinations of these modes of heat transfer. Conduction is the transfer of thermal energy between neighbouring molecules in a substance due to a

temperature gradient. It always takes place from a region of higher temperature to a region of lower temperature, and acts to equalize temperature differences. Conduction needs matter and does not require any bulk motion of matter.

Conduction takes place in all forms of matter such as solids, liquids, gases and plasmas. In

Solids, it is due to the combination of vibrations of the molecules in a lattice and the energy

Transport by free electrons. In gases and liquids, conduction is due to the collisions and diffusion of the molecules during their random motion.

Convection occurs when a system becomes unstable and begins to mix by the movement of mass. A common observation of convection is of thermal convection in a pot of boiling water, in which the hot and less-dense water on the bottom layer moves upwards in plumes, and the cool and denser water near the top of the pot likewise sinks. Convection more likely occurs with a greater variation in density between the two fluids, a larger acceleration due to gravity that drives the convection through the convecting medium.

Radiation describes any process in which energy emitted by one body travels through a medium or through space

absorbed by another body. Radiation occurs in nuclear weapons, nuclear reactors, radioactive radio waves, infrared light, visible light, ultraviolet light, and X- rays substances.

Heat conduction is increasingly important in various areas, namely in the earth sciences, and in many other evolving areas of thermal analysis. A common example of heat conduction is heating an object in an oven or furnace. The material remains stationary throughout, neglecting thermal expansion, as the heat diffuses inward to increase its temperature. The importance of such conditions leads to analyze the temperature field by employing sophisticated mathematical and advanced numerical tools, Schneider (1957).

The section considers the various solution methodologies used to obtain the temperature field. The objective of conduction analysis is to determine the temperature field in a body and how the temperature within the portion of the body. The temperature field usually depends on boundary conditions, initial condition, material properties and geometry of the body, Teixeira and Rincon (2009).

Why one need to know temperature field. To compute the heat flux at any location, compute thermal stress, expansion,

deflection, design insulation thickness, heat treatment method, these all analysis leads to know the temperature field, Fried,(1957).

The solution of conduction problems involves the functional dependence of temperature on space and time coordinate. Obtaining a solution means determining a temperature distribution which is consistent with the conditions on the boundaries and also consistent with any specified constraints internal to the region. Keshavarz and Taheri (2007) have obtained this type of solution.

There are several methods for measuring thermal conductivity and diffusivity in the laboratory. The methods can basically be divided into steady-state and transient methods. A good summary of the most often used techniques is given by Beck (1988). Several techniques have been applied in measurements of thermal parameters in situ, such as 'passive' methods based on either temperature gradients in a borehole as indicators of lithologic (conductivity) variation Conaway and Beck(1977) annual temperature wave in the uppermost 15-30 m of bedrock for diffusivity determination Parasnis(1974); Tan and Ritchie(1997) or direct measurement of geothermal heat flow density and simultaneous temperature gradient in a drill hole which can be used

for in situ 18 conductivity estimation Oelsner and Rosler(1981); Jolivet and Vasseur(1982). Various active methods using either cylindrical, line or spherical sources for generating either a continuos heating signal or a heat pulse in the investigated medium have been developed for measurements in boreholes or soft sediments for terrestrial, marine and lunar studies (e.g. Beck et al(1971); Sass et al(1981); Mussman and Kessels, (1980); Langseth et al., (1972); Davis(1988).

The basic theory of heat conduction in a cylindrically symmetric geometry is developed by Carslaw and Jaeger (1959), Jaeger (1955, 1958,1959) and Blackwell

(1953, 1954, 1956). They discussed analytical solutions for an infinitely long conductive cylinder which produces heat dissipating to the surrounding medium. The molecules in a segment of a system at high temperature vibrate faster than the molecules in other regions of the same or anothers systems which are at lower temperatures. The molecules with higher motions strike the less energized molecules and transfer some of their energy to the molecules at the colder regions of the system. For example, heat is transferred by conduction from the cars bodywork to the materials inside the car which are in touch with the cars

The element having

Heat conduction rate into the element = Q(X)

Heat conduction rate out the element = Q(x+dX)

Net rate of heat conduction into the element Qnet = Q(X) Q(x+dX)

If the heat is generated within the element due to resistance heating, chemical or nuclear reaction etc. And the rate of volumetric heat generation is g (W/m3).

Then rate of energy generation, Qgen = g (A dX)

Due to unequal heat transfer to and from the element, its internal energy will change.

The rate of change of internal energy,

bodywork.

= =

(1)

Q(X+dX) = Q(X) + () dX + 2 () +

2

Where, T = F(X, t), temperature of element as function of time and direction,

0C,

g = G(X, t), the function of time and direction, W/m3,

k =K(X), the function of direction, W/m.K,

C =specific heat of the material (solid having only one specific heat), J/kg.K),

M = mass of the element = ( A dX), kg,

2 + 3() + 3 +…………………

3

2! 3!

If the control volume is considered small enough, then the higher powers of dX such as dX2, dX3, etc. are very small, therefore, neglected from above equation and it reduces to

Q(X+dX) = Q(X) + () dX (3)

Substituting this equation in eq(2)., we get

A = area of element normal to the heat

– () dX + gAdX = C AdX

(4)

transfer, m2,

= density of the material, kg/m3, t = time, s,

Substituting

Q(X) = -kA

dX = directional thickness of element, m.

Then, – {-kA }+ g = C

Making the energy balance on the element.

Net rate of heat gain by conduction + rate of energy generation = the net rate of change of internal energy.

If the conducting material is isotropic, its thermal conductivity is independent of direction; it is treated as constant quantity, then

1 {A }+ = C

(5)

Qnet + Qgen =

Or [Q(X) Q(X+dX)] + g A dX = C

Where = k/ C is known as thermal

AdX

According to Taylors series

(2)

diffusivity

The above eq.(5) is in general coordinate system. It is one dimensional time dependent differential equation for heat conduction with constant thermal

conductivity. It is known as unidirectional governing equation for heat conduction.

Substituting the value of constant in equation (7), we get

This above eq.(5) in particular coordinate system by introducing proper area A and directional thickness dX as described below.

If there is no internal heat generation within the material, the above equation reduces to:

T(x) = [ 2 1 ] x + T

1

q = – k

q = -k 2 1

Q = q * A

(8)

1 {

1

The heat conduction rate Q is given by

A } =

Q = -kA

2 1 (9)

It is known as unidirectional Fourier equation.

Therefore if the heat is not generated within the solid then it reduces to unidirectional Laplace equation.

In Cartesian coordinate

{ } = 0 (6)

Integrating the above , we get

= c

T(x) =Cx + C1 (7)

T (0) = T1 = C1

T (L) =T2 = C (L) + T1 C = (T2-T1)/L

Equation (1-9) is the solution for the rate of heat transfer through a one dimensional equation. The equation suggests that, under some limiting conditions, conduction of heat through a solid can be thought of as a flow that is driven by a temperature difference and resisted by a thermal resistance, in the same way that electrical current is driven by a voltage difference and resisted by an electrical resistance. Inspection of equation (1-7) suggests that the thermal resistance to conduction through a solid is given by:

Thermal resistance RTH =

Figure: Rectangular Block Section

Figure: Triangular Block section

ASSUMPTIONS:

Conduction Heat Transfer Model

Material is isotropic.

Heat flow is in one dimension only.

There is no heat generation.

Steady state condition

Figure: Brass Material

Figure: steel Material:

Figure: Brass Material

Figure: steel Material

Figure: Temperature grid in Brass Material

Figure: Temperature grid in Brass Material

Figure: Temperature grid in steel Material

Conduction Heat Transfer Schneider Pdf

Figure: Temperature grid in steel Material

Conduction Heat Transfer Calculator

REFERENCES

Conduction Heat Transfer Examples

Blackwell, J.H., (1956).The axial- flow error in the thermal conductivity probe. Can. J.

Blackwell, J.H.,(1953) Radial-axial heat flow in regions bounded internally by circular cylinders. Can. J. Phys., 31,472-479.

Blackwell, J.H., (1954). A transient-flow method for determination of thermal constants of insulating materials in bulk part I -Theory. J. Appl. Phys., 25, 137-143.

Schneider P.J,(1957), Conduction Heat transfer, Addison Wesley,

Carslaw, H.S. and Jaeger, J.C., 1959. Conduction of heat in solids. Oxford University Press, Oxford, 510 pp.

Fried, E; (1970) Thermal conduction contribution to heat transfer at contacts 24-33

Parasnis, D., (1974). Estimates of in situ thermal diffusivity of the ore-bearing rocks in some drillholes in the Skellefte field (N. Sweden) using the annual temperature wave. J.Geophys. 40, 83-95.

Conaway, J.G. and Beck, A.E., (1977). Fine-scale correlation between temperature gradient logs

and lithology. Geophysics, 42, 1401-141

Oelsner, C. and Rosier, R., (1981). Eine Bohrlochsonde zur gleichzeitigen Messung von Warmestrom und

Warmeleitfahigkeit in situ. Neue Bergbautechnik, 11, 266-268.

Jolivet, J. and Vasseur, G., (1982). Sur un essai de mesure directe du flux geothermique in situ. Ann. Geophys., 38, 225-239.

Davis, E. E., 1988. Oceanic heat- flow density. In: R. Haenel, L. Rybach and L. Stegena ( eds.), Handbook of Terrestrial Heat- Flow Density Determination, Kluwer, Dordrecht,pp. 223-260.

Tan, Y. and Ritchie, A.I.M., (1997). In situ determination of thermal conductivity of waste rock dump material. Water, Air and Soil Pollution, 98, 345-359.

Keshavarz P and Taheri M, (2007), An improved lumped analysis for transient heat conduction by using the polynomial approximation method, Heat Mass Transfer, 43, 11511156