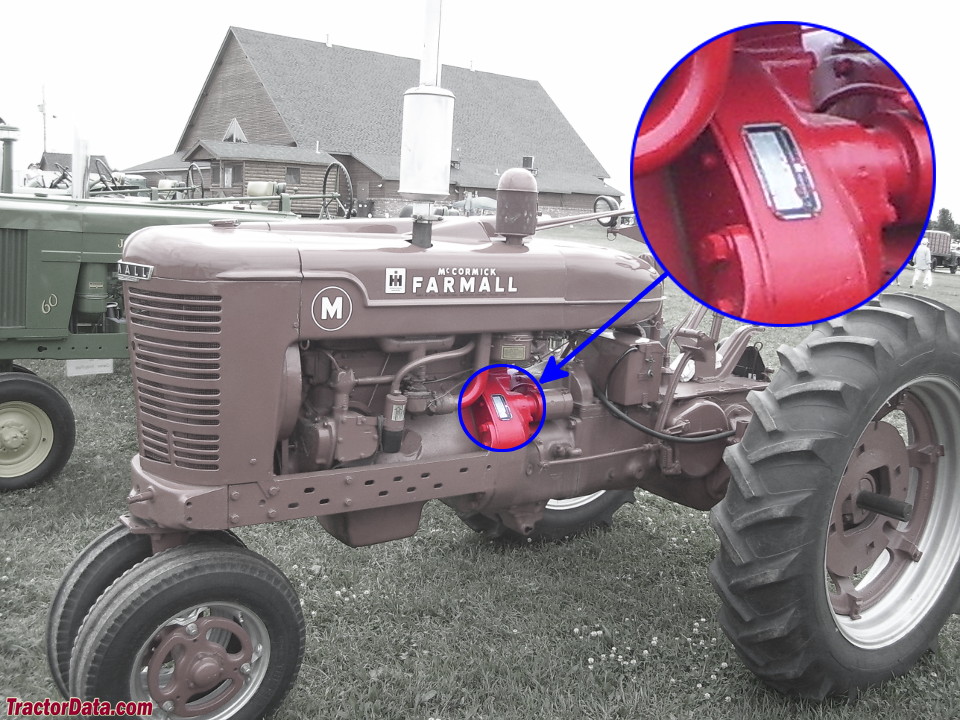

Use the chart on the right to translate the letter code into a year. For example, this picture shows a cylinder block cast date of 8.26.Q, which was August 26, 1947. The number below the casting date is 251341R1, which is the cylinder block part number. This example is 6.9.Y, or June 9, 1953.

Farmall Tractor Fuel System

- Please check your serial number of your Farmall tractor before ordering, many Farmall tractors had changes made during their production lifetime and as a result some parts may be different depending on the serial number. Your Farmall tractor or International tractor may use either a magneto ignition system or a distributor ignition system.

- 1947 Farmall M: 1946 Farmall M: 1940 Farmall A: 1939 Farmall F14: 1937 Farmall WK-40: 1937 Farmall WK-40 Standard: 1937 Farmall WK-40 right side: 1937 Farmall.

Farmall Tractor Exhaust System

Farmall Tractor Cooling System

Fan Assembly |

Farmall Tractor Electrical System

| Switches |

Farmall Tractor Clutch & Flywheel

Clutch Parts |

Farmall Tractor Decals, Emblems, andSeats

Early Style Inlayed Pan Seat | Seat SpringsAnd Shocks |

Farmall Sheet MetalParts

| Battery Boxes | Tool Boxes | PTO Shields |

| CUB Hood Extensions | Pedal Guard | Front Grill |

| Grill Insert | Rear Fenders |

Farmall Tractor Parts

| Steering Wheels | Brake Bands | Brake Discs |

| Wheel Bearings | Air Cleaner Cap | Universal Gauges |

| Original Style Gauges | Steering Shaft Parts | Cub Transmission Parts |

| Throttle Lever | Gas Caps | Rear Axle Housing |

| Draw Bar Parts | Gear Shift Knob | |

| Replacement Rims | Rear Wheel Clamp | Front Rim Clamp |

| Radiator Support | Light Bracket | Clutch Inspection Plate |

| Pre Cleaner Assembly |

Books And Manuals

Farmall Manuals | I & T Repair Manuals |

Copyright © 2003, 2005

Restoration Supply Tractor Parts

All rights reserved

| Cost: For a lot of years the Farmall M was in the big leagues--one of the few tractors with the power, capability, styling, and popularity to become a lasting symbol of modern farming. It was one of the most successful tractors of all time, which has two implications for current sales: One, lots of people still really like them, which drives the price up. Two, many of the 300,000 or so that were built are still around, which drives the price down. Typical auction prices for average Ms in running condition are around $1200, here in the midwest. A non-running 'parts tractor' might go for just a few hundred; a restored 'show tractor' might go for three or four thousand or even more, especially if it's a Super MTA or Super MTA Diesel, the last versions of the M. |

Severely worn, cracked, or flat tires will drive the value of the tractor down by a few hundred dollars; new or nearly new ones will drive it up by a similar amount. Overall condition of the sheet metal is another big variable, with the front grille being especially likely to be bent up or missing the little insert near the bottom. Even if that insert is gone, check to see if the bottom bar of the grille itself is still there--the inserts are readily available from aftermarket suppliers, but if that lower bar has been cut out you'll need more than the insert to fix it. If the gauges, lights, and starting and charging systems work, it'll save you the cost of repairing or replacing them later. Optional equipment like fenders, a belt pulley, the toolbox that mounts on the lightbar, wheel weights, etc., are less expensive to buy already on a tractor than as separate individual parts. Oil leaks from beneath the engine, brakes, axles, or power takeoff shaft aren't unusual and likely don't mean anything serious, but it can be a lot of work to fix them. (Click here for photos and notes about minor repairs I've made to my 1950 M). |

Hydraulics:

Most Ms have an internal 'Lift-All' hydraulic system for tractor-mounted implements like cultivators or a loader. An auxiliary hydraulic valve was available as an option to provide two-way pressure for a remotely-mounted hydraulic cylinder, such as might be mounted on a trailing implement like a disk or brush hog. Those valves and related components are frequently auctioned on eBay, so you can add them to a tractor that didn't previously have them, but it'll likely cost $150 or more by the time you get it all set up.

| Auxiliary hydraulic valve | ||

Some Super Ms built in 1953 or 54 (and regular Ms with after-market equipment--see below) have an engine-driven hydraulic pump, as opposed to a transmission-driven pump. That means hydraulic implements can be operated independently of the transmission clutch, which is a nice feature. The 'live' pump also has more pressure and a higher volume flow, so you can lift heavier loads and lift them faster than you could with the original transmission-driven pump. If there are hydraulic hoses running along the right side of the tractor engine, from up by the distributor to back under the gas tank, the tractor has live hydraulics. (The live pump is driven by the timing gear train, the same thing that turns the distributor shaft, so the hoses have to snake alongside the engine to reach the pump).

If you're going to add a live pump to a tractor that didn't previously have one, check the spacing of the two top bolts on the distributor drive (it should be about 3' for older Ms, and about 3-1/2' for newer ones and Super Ms). IH pumps will likely only fit the wider spacing, but you may be able to find a pump made by an after-market supplier that will fit the narrower spacing. |

Mike Sloane wrote:

| '...I bought a used IH hydraulic pump that fits in place of the distributor drive between the timing gear and the distributor (that was $250 from Biewers Antique Acres). Then I was fortunate to locate a used hydraulic valve and some other parts that were originally from a JD combine, complete with some long curved handles. A bracket was made for the valve, and I mounted it on the right axle, with the curved handles coming right at hip level when sitting. I bought various hoses, adapters, reservoir, and filter from Northern, a Worksaver Farmall 3-point hitch kit, and a 2x8' cylinder from CT. Because the valve is a two way valve, I rigged up the lift cylinder for two way operation - it is much faster going down that way, but I needed one extra hose. If I could have located a used OEM reservoir from a parts tractor, it would have made a neater job of it, but I ended up putting the reservoir under the seat - the battery remained under the gas tank. 'Does it work? Yes, it works fine. How much did it cost? I think I spent about $800 all together. Was that worth it? I don't know. It was interesting and maybe fun to work through the whole process, but to spend $800 on a $1600 tractor was probably not an efficient operation -- I could probably have bought a similar 400 with fast hitch and live hydraulics for about the same money. Fast hitch adapter kits from 2-point to 3-point are only about $60. Also, if I had known, I would have bought the Saginaw 3-point kit, which comes with 2 cylinders and saved at least $200 - that would have made the job much more economically sensible plus I could have retained the Farmall swinging drawbar (you can't with the Worksaver kit unless you buy yet another adapter). 'What you wind up with is a Cat II hitch with no draft sensing. It does have sway control and good position control, but the only way to adjust the individual arms is by turning the lift screw sleeves -- no hand crank from the operator's seat like a regular 3-point hitch. Since I only intend to use the hitch with a brush cutter, platform lift, or boom crane, none of those deficiencies are of any consequence, but I could never plow with that arrangement.' |

| '...We purchased a 3 point hitch for our M (regular old '50 M, but with an M&W live hydraulic pump) last year from Saginaw County Tractor Parts. They advertise (with a picture that doesn't do it justice) in Red Power magazine. They are cheaper ($575 at the time - $595 now). Includes two cylinders, painted IH red, fits like a glove, impeccable workmanship, Zerk fittings on every bearing service, and non-slip material on anything you might use as step. The cylinders will be set up as one way or two way (down pressure) based on what you tell them you want. The ad says they are the finest--and IMHO they are the best--based on the ones we have seen. They have the roll-over 'ball' type mounting holes in the lift arms to accept Cat I or Cat II three-point equipment. 'The valve is the IH auxiliary control valve (two way hydraulics) as depicted in the Operators Manual. Ours uses the belly pump reservoir and has fitting on the control valve to give 'power beyond' to another valve if we needed to.... The Saginaw Three Point hitch with two cylinders w/down pressure hooked up to the IH valve and we have use it extensively (maybe with a tad of abuse) it works flawlessly. Never ran into anything it worked at getting up/ down - whatever - Boom Pole, 6ft Box Blade, 6ft Bush Hog, Slip scoop-- (BIG rocks), and carry all. If will lift the Back end (Down Force) of the Tractor too easily if you know what I mean. 'There is a lot I'm leaving out so if you have any specific questions from a customer's perspective let me know. I have no conection to Saginaw other than as a satisfied customer.' |

| 'I also purchased my 3 point hitch from Saginaw Tractor. In regard to its capacity if used with a single cylinder and usefulness with the old belly pump hydraulics, I've gone through three stages: 'Stage I (single cylinder, no down pressure). I first hooked it up to just a single cylinder from the one way valve with a breather on the top cylinder port and I was able to move 1000lb hay bales with it. I once tried to pick up a transmission and axel assy from a Super C parts tractor. It couldn't lift it, but if I lifted it with something else, it would just barely hold it up in the air. I decided not to risk it and used an engine crane to hold it while I backed a truck under to haul it off. 'Stage II (single cylinder, up/down pressure, live hyd). When I got tired of not having down pressure and not being able to adjust the hitch when the clutch was in, I upgraded to a live hydraulic system from a Series II Super M and added a two spool valve for the 3 point and 1 remote. As far as cost is concerned, I ended up with: 225 pump, 100 reservoir, 90 batt box/seat base, 40 seat suspension, @100 in hydraulic lines, 180 two spool valve that I mounted on the seat box convenient to right hand. I took one circuit to the 3 point and used the second valve as a remote for the wheels on a cutting disc and the gate on a Gehl round baler. Since the reservoir replaces the rear fuel tank support, I lost the regulator mounting (which was a blessing in disguise since it didn't work anyway) and switched to a 12V alternator at the same time. This was an early SM (Series I with the belly pump hydraulic system). I got a lot of the parts from either Steel Wheel or Mathis Equip that advertise in Red Power. 'Stage III (twin cylinders). Well I finally found a way to damage the hitch. I was picking up another tractor (a Farmall B without the motor) from a trailer. I couldn't lift it but found I could hold it up if I jacked the trailer up then let it down from under the tractor. But didn't get quite enough clearance and when I dragged it off the trailer the rockshaft on the hitch bent so that one lift arm was a good 7-9 inches lower than the other at the tip. I first thought something on the hitch frame was bent or broken, but the frame was fine, just the rockshaft twisted. So I blocked the low arm and used the down pressure to straighten out the rockshaft forcing it the other way. Then I went and got the second cylinder that had been collecting dust and routed new hydraulic lines to feed both cylinders together. I tried again to lift the parts B tractor and this time with the extra capacity I lifted it right off the ground and drove away with it.' |

| A Saginaw hitch on a Farmall 400, photographed and owned by ATIS member Goodwrench. Click on the picture to go to a larger, higher-resolution image. |

| Power Take-Off and Torque Amplifier: | |

| The Super MTAs, built only in 1954, were the first Farmalls to have a live power takeoff. Live power wasn't a factory option on older Ms and Super Ms, but an after-market hand clutch was available that provided a live pto. Many tractors still have those clutches (made by M&W), mounted over the left brake housing, but parts for them are hard to come by. ATIS member Stan Bass recently had to fabricate new disks for the M&W clutch on his Super M, after being unable to find enough replacement disks. Here's his description, as posted to the ATIS Farmall list: | |

| 'For those of you that recall, last fall I posted a couple of questions on the main list about repairing the hand clutch on my Super M. The update is that it now has new clutch discs and appears to be working great :-) 'We measured the NOS disc I found and drew it in autocad, fed that through some other magic (I lost track) eventually to the CNC mill controller. We did several test cuts out of wood until we matched the NOS disc perfectly. We bought a large sheet of the clutch material and milled them out. The material was very hard on the cutter bits, a carbide bit barely lasted through one disc if we were lucky. I put the tractor back together the first weekend using 2 new discs and the NOS disc (since we matched the disc up so well, I wasn't worried about being able to reproduce the NOS disc). Doing just small quantities like this it ended up costing about $100 per disc. 'My tractor had apparently sat for a long period at some point as the metal parts inside of the hand clutch (especially the brake drum which has the teeth that mate to the discs) were rusted and pitted. What surprised me was that the old fibre discs were not worn down in their thickness, but their teeth had been chewed off! My M was just driving off the stubs left on the teeth from the last disc. The teeth on the fibre discs are apparently designed with very tight clearances so I spent most of my time with a file removing scale and getting a good surface on the teeth in the drum before they would slide in.' | |

| Stan also found out that M&W is still operating and may be able to help with information, and can be reached at (800) 221-2855. Super MTAs also introduced the 'Torque Amplifier' (hence the 'TA' designation), an IH innovation used on many following Farmall series tractors. It was a planetary gearset that let the operator shift to a lower range while on the go, increasing torque and decreasing ground speed. If you're looking at an MTA, check to be sure the TA works--you'll often see tractors advertised as having a 'good TA' or 'bad TA,' or something like that. They can be rebuilt or replaced if they're worn out, and are readily available from suppliers such as those listed below. | |

Farmall M Serial Number Chart 2019

| Starting and Running: | |

| Most Ms have an electric starting and lighting system, but not all do. Many have been converted to 12-volt systems, but the original 6-volt systems will work fine if the tractor is tuned up well and if the temperatures aren't bitterly cold. If you're buying a new 6-volt battery, get the biggest one, with the most 'cold cranking amps' (CCA), that will fit in the battery box. The wiring harnesses on old tractors are often in pretty bad shape, but they're fairly simple to replace since everything is accessible. Check out Robert Melville's Farmall wiring diagrams, and suppliers like Brillmans, Rhode Island Wire or OEM Tractor Parts for original-looking wire and components. The brake pedals should have about 1-1/4' of free play--the distance you can push the pedals in before the brakes start to take hold. They should be matched, so that both brakes engage at the same time when the pedals are latched together. Look for oil accumulation beneath the brake housings, which is a sign of oil leaking past the seals and soaking the brake bands. The clutch pedal should have between 1/2' and 1' of free play. I've bought two Ms over the years and taking the tractor for a road test was a clincher both times--it's just a lot of fun to hear that smooth Farmall hum and to watch the world go by from up there. And it's an opportunity to test the clutch and the gears, and to listen for unusual sounds from the transmission, and it's a decent way to judge engine lugging power as you start out in 5th gear from a dead stop. But be careful: Farmall Ms are fast in 5th gear, like 16 or 17 miles an hour. When you're up high on that seat, on a vehicle with no suspension, that's cruising right along. It's no problem on a smooth road, but hitting a bump or a pothole at that speed could bounce you right off the seat. Start slowly and get comfortable with the tractor, the steering, the brakes, and the road before you try the 5th-gear test. As someone else on the AT forum posted, Ms are notorious for having a worn worm gear or sector gear in the steering, which can cause the front wheels to shake in high gear. You can check for this when driving the tractor. Even at low speed, you'll be able to tell if there's a lot of free play in the steering--i.e., if you can turn the steering wheel quite a bit without actually turning the front wheels, or if the front wheels turn back and forth a bit on their own. | |

| Narrow-front Ms can be hard to steer when stopped or when moving very slowly, but are usually fine once you're moving faster. Backing into a tight space can be a challenge, since when you're half turned around with only one hand on the wheel, it can be hard to put much weight into steering. I think old Farmalls tend to be harder to steer than old John Deeres, since the Farmall engine is right up front by the front wheels, while Deere engines are back close in to the rear axle. (I think this is also why rear-wheel weights seem to be more common on Farmalls than on comparably-sized John Deeres, since that Deere engine placement helps traction). A spinner knob on the steering wheel can help, and is hugely fun to use when turning the tractor around at the end of a row, but it can also whack your hand good and hard if the front wheels hit a rock or a furrow or something, and the steering wheel suddenly spins. None of the Ms came with power steering, although there were aftermarket companies like Behlen and Char-Lynn that made power-steering pumps for them. I'd think that Farmall parts suppliers like Bates Corporation (Bourbon, IN, 800-248-2955), Steel Wheel Ranch (Everest, KS, 785-548-7437), Carter and Gruenewald (Brooklyn, WI, 608-455-2411), Sam's Tractor Parts (Noxapater, MS, 888-333-1690), Mathis Equipment (Cairo, MO, 816-295-4456), or Berkshire Implement (Royal Center, IN, 219-643-3115) would have some of those pumps for sale. I don't think a wide front end would make much difference in the ease or difficulty of steering, but they're likely to be available from those same suppliers if you wanted to try it, or if you wanted to convert for other reasons. | |

| One other thing you might check: Ms sometimes had a problem in the rear-end transmission. There are two big 'bull gears' in the final drive, centered on the rear axles, one on each side. The bearings that support these gears wear out sometimes, and so a ball bearing would drop down and get caught between the gear and the housing, and punch through. The problem could be fixed, and wasn't all that common to begin with, so unless there's a leaking patch in the bottom of the rear end your tractor is probably fine. Just thought I'd mention it as long as we're talking Ms. | |